vickers hardness test glass|vickers hardness testing machine diagram : advice The Vickers test can be used for all metals and is one of the widely used test among hardness tests. The unit of hardness is known as the VICKERS PYRAMID NUMBER (HV) or DIAMOND PYRAMID HARDNESS (DPH). Acompanhantes em Goiânia. Veja garotas em fotos reais. Todas são conferidas periodicamente para que você tenha uma acompanhante disponível rapidamente

{plog:ftitle_list}

{{page.OGdescription}}

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.

vickers hardness testing procedure

Originally developed by the Vickers Company of the United Kingdom in the 1920s to test alloy armor plates, the Vickers Hardness Test is still utilized to evaluate welded joints and heat-affected zones (HAZ) of metal .

A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds .The Vickers test can be used for all metals and is one of the widely used test among hardness tests. The unit of hardness is known as the VICKERS PYRAMID NUMBER (HV) or DIAMOND PYRAMID HARDNESS (DPH). Vickers hardness is defined as the average force per unit area on the surface area of the indentation retained after the unloading of the indenter, which reflects the ability of the specimen to resist linear residual deformation.

The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. While it can be used to test the hardness of metals and .The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low . Vickers hardness testing is a preferred method for assessing the hardness of all types of metals, offering the most comprehensive range of hardness scale measurements . The Vickers hardness test has two distinct force ranges, “Microindentation Vickers” (10 – 1000g) and “Macroindentation Vickers” (1 – 100kg), to cover all testing requirements. The indenter is the same for both .

Hardness testing according to current standards. Our hardness testing machines support a wide load range for the Vickers, Brinell and Knoop test methods. All methods are covered with the ISO 6506 / ASTM E10, ISO 6507 / . Ceramics, glass, coatings, small samples: 10-1000 gf: Asymmetrical Pyramid: ASTM E384, ISO 4545: Leeb (Rebound) Metals, Large parts: Portable, suitable for large parts: . Vickers Hardness Test. The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to hard ceramics, and is .

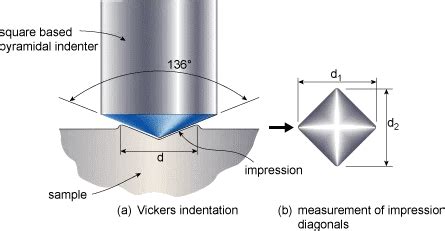

Micro Vickers hardness: The Vickers hardness test method consists of indenting the test m aterial with a diamond indenter, in the form of a right pyramid with a square base and an an gle of 136 The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness (1) The geometrical shape of the indentation is always similar, while the load can be varied. . Glass: Silica: 700-750: Soda lime glass: 540~580: optical glass: 550-600: Polymer .test, (b) Vickers hardness test, (c) Rockwell hardness test, (d) Rebound or Dynamic hardness test, (e) Scratch test (f) Meyer . Vickers Micro hardness Measurement of Glass-Nanocomposites 19 Journal of Material Science and Mechanical Engineering (JMSME) Print ISSN: 2393-9095; Online ISSN: 2393-9109; Volume 1, Number 1; October, 2014 .Glass wool (originally known also as fiberglass) is an insulating material made from fibers of glass arranged using a binder into a texture similar to wool. . The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The .

The scratch process of a brittle material such as glass with a Vickers indenter under linearly increasing normal load can be divided into three stages according to the deformation and failure mode, i.e., micro-ductile regime, micro-cracking regime and micro-abrasive regime [34, 35], as shown in Fig. 1.Elastic-plastic deformation dominates in the stage . The initial data, including the density, Vickers hardness, and the chemical atomic contents of the oxide glasses chemical elements, were extracted from the SciGlass database which collects the properties and chemical compositions of the glasses reported in literature and patents [45].The oxide glasses are defined as materials having an atomic oxygen fraction of at .

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness. .choice of hardness in the various Vickers IF equations. The usual convention in the hardness community, and the one that is adopted in every formal hardness standard in the world, is to define Vickers hardness (HV) as the load divided by the contact area of the four faces of the indentation. This leads to the standard definition: (4) ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals.

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.For testing the hardness of glass and glass-ceramics, two methods of test have been discussed, namely the Vickers hardness test and the Knoop hardness test. Both tests involve certain difficulties when carried out. The results of a round robin testing survey, carried out in 1974 by the International Commission on Glass (ICG) to compare both .

vickers hardness testing machine price

It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. . The . Basic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness de.

This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and .Vickers Hardness (200g load) 2Unstrengthened 555 kgf/mm . ependent upon actual testing conditions. Reagent Time Temperature Weight Loss (°C) (mg/cm2) HCI – 5% 24 hrs. 95 0.6 . Damage Resistance Performance Scratch Test Performance Gorilla® Glass 3 (with IOX) Soda Lime (with IOX) 0 4000 8000 12000 16000

To measure the Vickers hardness, specimens prepared using a standard rectangular mold of 62mm length, 10 mm breadth and 2.5 mm thickness. Vickers Hardness number measured using Vickers hardness test apparatus having square based diamond pyramid as indenter.Vickers Hardness (Mean±SD) Empty Cell: Before grinding After grinding; Curtis et al., 2006: Lava frame: Specimens randomly selected and submitted to a Vickers hardness test with a diamond pyramid head of a Duramin-1 Vickers hardness tester (Struers) under a predetermined load (9.807 N) over 15 s to induce a diamond-shaped indent. The size of .

These include metals, ceramics, glass, and graphite. It is also ideal for thin slices and small-sized samples. High Accuracy: It can provide high test accuracy and repeatability. It is especially suitable for measuring high-hardness materials. . Vickers Hardness Test: A diamond-shaped diamond indenter is used to apply a load on the surface of .The acrylic resin VC and VW presented higher hardness values than VF and QC resins. Moreover, GFR increased the Vickers hardness of resins VW, VC and LT. . types of acrylic denture base resins with and without glass fibre reinforcement . Specimens were then submitted to Vickers hardness testing with a 25-g load for 30 s. All data were . EN ISO 6507-1 specifies he following are the three ranges of test force and their corresponding Vickers hardness test designations: F ≥ 49.03 N - Designation: HV 5 - Standard Vickers hardness test method for testing metals and materials with a medium to high hardness range. 1.961 ≤ F < 49.03 N - Designation: HV 0.2 to

vickers hardness testing machine diagram

using too much force during hardness test

Glass Hardness Vickers. Mineral glass has a hardness of 500-800 and is suitable for use in a variety of applications. Measuring Glass Hardness With Mohs And Vickers Tests. The hardness of glass has a significant impact on its strength and durability. The Mohs test and the Vickers hardness test are widely used to determine glass hardness.

Knoop: Knoop hardness testing is particularly useful for testing brittle materials, such as ceramics and glass. When to Use Vickers Hardness Testing Testing Metallic Materials. Vickers hardness testing is ideal for assessing the hardness of metallic materials, including ferrous and non-ferrous alloys.In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.

using wd hard drive during drive tests ok

using western digital diagnostics to test hard drive

Resultado da em Goiânia, Goiás Só na Oi Fibra você tem alta velocidade e super .

vickers hardness test glass|vickers hardness testing machine diagram